Journal of the Ceramic Society of Japan

vol. 134, no.1, 2026

◆Note◆

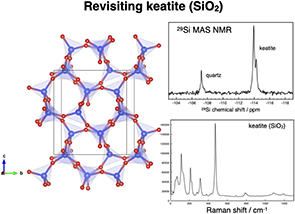

Structural and spectroscopic characterization of keatite (SiO2)

https://doi.org/10.2109/jcersj2.25143

https://doi.org/10.2109/jcersj2.25143

Masami Kanzaki and Xianyu Xue

1

Keatite, a polymorph of silica rare in nature, was synthesized by hydrothermal treatment of silicon and water at 100 MPa and 600 °C. The crystal structure of keatite at 24 °C was refined by the Rietveld method using synchrotron X-ray diffraction data. The obtained structure is consistent with the results of previous studies in which some constraints were imposed during refinements. The 29Si MAS NMR spectrum of keatite shows two peaks at −113.9 and −114.3 ppm, which can be assigned to Si at the Si1 and Si2 sites, respectively. The Raman spectrum of keatite shows a prominent peak at 473 cm−1, which is attributable to the Si–O–Si bending mode of the 5-membered ring. These spectra, reported for the first time, are expected to be valuable for the identification of keatite in synthetic and natural samples.

◆Full papers◆

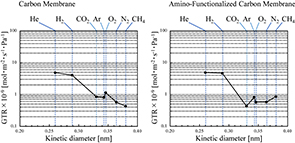

Synthesis of amino-functionalized amorphous carbon membranes via glucose-solution hydrothermal method

https://doi.org/10.2109/jcersj2.25124

https://doi.org/10.2109/jcersj2.25124

Yosuke Nakamura, Naoki Arimitsu, Sachiko Matsushita, Yasuhide Mochizuki, Akira Nakajima and Toshihiro Isobe

5

There remains an ever-increasing interest in carbon membranes due to their chemical properties and heat resistance. This study aims to investigate the influence of the amino-functionalization of amorphous carbon membranes on the H2/CO2 separation ability. Amino-functionalized amorphous carbon membranes were synthesized on porous alumina via a hydrothermal method using a glucose solution with added ammonia. The gas permeabilities and other characteristics of the membranes were evaluated. The electron probe microanalyzer (EPMA) results indicate that the carbon was deposited on the surface and inside of the alumina support, and the carbon deposited region inside varied depending on the ammonia concentration. The Fourier-transform infrared spectroscope (FT-IR) analyses suggest that the membranes hydrothermally treated with ammonia solution include nitrogen atoms in the form of functional amino groups. The gas transmission rate (GTR) results indicate that the H2/CO2 gas selectivity for the sample hydrothermally treated with ammonia solution (approximately 12.2) was higher than that of the untreated sample (approximately 4.7).

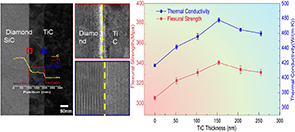

Effect of TiC layer thickness on the thermal conductivity and mechanical properties of Diamond/TiC/SiC composites

https://doi.org/10.2109/jcersj2.25112

https://doi.org/10.2109/jcersj2.25112

Zhao Huang, Xiaomeng Li, Haotian Yang, Zhaoxuan Yan and Bo Chen

10

Diamond-reinforced silicon carbide (Diamond/SiC) composites, with their exceptional thermal conductivity and mechanical properties, are considered ideal packaging materials for high-power-density and highly integrated electronic devices. However, their fabrication challenges and insufficient interfacial performance, particularly interfacial defects caused by acoustic and lattice mismatches, significantly limit further performance improvements. To address these issues, this study utilized stereolithography-based 3D printing technology to achieve rapid and precise material shaping, combined with magnetron sputtering to introduce a Ti layer, followed by reactive infiltration to fabricate Diamond/TiC/SiC composites. Advanced characterization techniques, including scanning electron microscopy, transmission electron microscopy, and energy-dispersive spectroscopy, were employed to systematically analyze the effect of TiC interlayer thickness on the interfacial structure and composite performance. The results revealed that the introduction of the TiC interlayer formed a quasi-coherent interface with good lattice matching between diamond and SiC, effectively reducing acoustic mismatch and interfacial dislocation density, thereby significantly enhancing interfacial performance. The thermal conductivity and flexural strength of the composites exhibited a trend of initial increase and subsequent decrease with increasing TiC interlayer thickness. When the TiC layer thickness reached 154 nm, the thermal conductivity and flexural strength achieved maximum values of 478 W/(m·K) and 342 MPa, respectively, representing improvements of 14.6 and 11.4 % compared to composites without the TiC interlayer. This study proposes a strategy to enhance the overall performance of composites by constructing quasi-coherent interfaces, optimizing interfacial bonding, and mitigating acoustic mismatch, providing valuable theoretical and technical guidance for the interfacial design of Diamond/SiC composites and the development of high-performance thermal management materials.

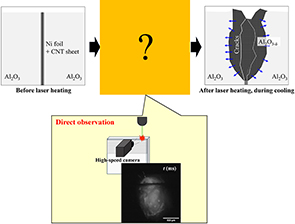

Direct observation of the joint interface between Al2O3 plates with nickel foil and carbon nanotube sheets as insert materials during laser welding

https://doi.org/10.2109/jcersj2.25130

https://doi.org/10.2109/jcersj2.25130

Hirosuke Sonomura, Keigo Tanaka, Takuto Yamaguchi, Takeshi Tanaka and Tomoatsu Ozaki

18

Manufacturing processes using 3D additive manufacturing of ceramics have become a rapidly growing area of research. The development of a laser welding technology for thick ceramics would improve productivity and reduce manufacturing costs. In this work, 3-mm-thick Al2O3 plates were laser butt joined with Ni foil at different powers and with or without a carbon nanotube sheet, and the mechanical properties and microstructures of the joints were investigated. Plate edge surfaces were metallized with Mo by friction stirring as a pre-treatment to improve wettability and reduce thermal expansion differences by gradually changing the thermal expansion coefficient of the material. The 3-mm-thick laser butt joints obtained at 65 W and with a carbon nanotube sheet showed a deep reaction from the surface towards the interior under laser keyhole welding conditions, resulting in a tensile strength at 0.64 MPa. Tensile strength was insufficient because the weld bead was concave owing to spatter and there were cracks within the weld and heat-affected zone from the surface towards the interior. Crack initiation mechanisms and improvement methods were discussed by direct observation of the joint interface during laser welding.

Preparation of brookite-type titanium dioxide particle layer on titanium surfaces via hydrothermal treatment and evaluation of in vitro apatite-forming ability

https://doi.org/10.2109/jcersj2.25119

https://doi.org/10.2109/jcersj2.25119

Satoshi Hayakawa, Yushi Nakamoto, Seiya Kojima, Noriyuki Nagaoka, Takuya Kataoka and Tomohiko Yoshioka

24

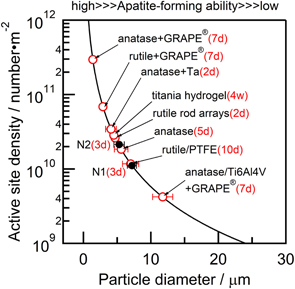

In this study, we prepared a brookite-type titanium dioxide particle layer on the surface of titanium substrates via hydrothermal treatment in aqueous urea solutions containing sodium chloride (NaCl) and examined its in vitro apatite-forming ability. Increasing the urea concentration suppressed the formation of anatase-type titanium dioxide on the titanium substrate, forming a particle layer composed of pure brookite-type titanium dioxide. The size and packing density of brookite-type titanium dioxide particles formed on the titanium substrate increased with the NaCl concentration in a 7.0 mol·dm−3 urea solution. When titanium substrates hydrothermally treated in aqueous solutions of 7.0 mol·dm−3 urea and 2.0 mol·dm−3 NaCl were soaked in a simulated body fluid for various periods up to 7 d, the substrate surface was densely covered with hemispherical apatite particles (5.3 µm in diameter) within 3 d, indicating that the brookite-type titanium dioxide particle layer had an excellent apatite-forming ability comparable to that of the anatase-type titanium dioxide particle layer.

Structure and acid resistance of fluoride-treated hydroxyapatite particles

https://doi.org/10.2109/jcersj2.25078

https://doi.org/10.2109/jcersj2.25078

Satoshi Hayakawa, Kazuki Ando and Tomohiko Yoshioka

31

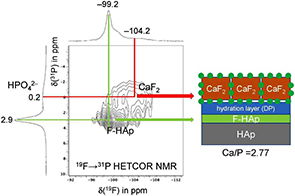

Topical fluoride is used in clinical dentistry to prevent dental caries. The primary reaction product formed on the tooth surface after topical fluoride application is calcium fluoride (CaF2). In this study, we investigated the effect of deposited CaF2 on the acid resistance of fluoride-treated hydroxyapatite (HAp). Commercial HAp particles were treated with two types of fluoride-containing acetic acid-sodium acetate (Ac-AcNa) buffer solutions, with and without the addition of phosphate ions. X-ray diffraction (XRD) and nuclear magnetic resonance (NMR) analyses confirmed the formation of fluorine-substituted hydroxyapatite (F-HAp), along with a hydration layer containing calcium phosphate and CaF2. Phase composition analysis revealed that the presence of phosphate ions in the fluoride treatment solution reduced the amount of CaF2 deposited. Acid resistance evaluation and phase composition analysis indicated that the initial dissolution rate of the fluoride-treated HAp in Ac-AcNa buffer solutions decreased on surfaces densely covered with CaF2 particles.

Role of apatite-type lanthanoid silicate promoter in PdO/Ln10Si6O27/γ-Al2O3 catalysts for catalytic combustion-type methane sensor: Contrasting trends between oxide-ion conductivity and sensor performance

https://doi.org/10.2109/jcersj2.25141

https://doi.org/10.2109/jcersj2.25141

Wonjoon Lee, Shinji Tamura and Nobuhito Imanaka

38

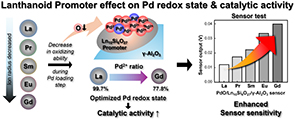

Apatite-type lanthanoid silicates (Ln10Si6O27; Ln = La, Pr, Sm, Eu, Gd) were investigated as promoters for PdO/γ-Al2O3 catalysts to enhance the performance of catalytic combustion-type methane sensors. X-ray diffraction and fluorescence analyses confirmed successful synthesis of phase-pure Ln10Si6O27 and PdO/Ln10Si6O27/γ-Al2O3 catalysts with compositions close to the intended stoichiometry. All sensors exhibited fast responses (T50 ≈ 10 s) and excellent linearity (R2 > 0.990) in the range of 0–1000 ppm CH4. Remarkably, the PdO/Gd10Si6O27/γ-Al2O3 sensor enabled quantitative CH4 detection at 320 °C, the lowest operating temperature among the tested catalysts. Interestingly, sensor sensitivity increased systematically with increasing lanthanoid atomic number, opposite to the trend expected from the oxide-ion conductivity of Ln10Si6O27, which decreases from La to Gd. Detailed analyses revealed that this discrepancy originated from catalytic activity and oxygen release properties rather than bulk conductivity. H2-TPR results demonstrated that PdO/Gd10Si6O27/γ-Al2O3 released active oxygen species more readily at low temperatures than the La-based catalyst. XPS further showed that the Pd2+/Pd0 ratio decreased from La to Gd, with the Gd-based catalyst achieving a balanced distribution that facilitated continuous redox cycling and sustained oxygen supply. This optimized Pd redox environment enhanced the proportion of complete methane oxidation, resulting in higher combustion heat and improved sensor output. These findings highlight that the performance of catalytic combustion-type methane sensors is governed not by intrinsic oxide-ion conductivity of the promoter, but by promoter–PdO interactions controlling Pd redox states and oxygen release dynamics. The results provide new insights into the design of advanced methane sensors operating at lower temperatures with higher sensitivity.

◆Technical report◆

Preparation of air-stable Li6.25Al0.25La2.8Mg0.3Zr2O12 sintered body

https://doi.org/10.2109/jcersj2.25128

https://doi.org/10.2109/jcersj2.25128

Susumu Nakayama

46

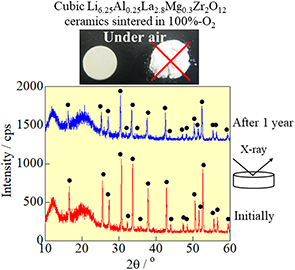

Cubic Li6.25Al0.25La3Zr2O12 exhibits high Li ionic conductivity (>3 × 10−4 S·cm−1) at room temperature: however, its sintered body disintegrates upon prolonged exposure to air. To prevent this collapse phenomenon, this study sintered Li6.25Al0.25La3−0.67xMxZr2O12 (M = Mg, Ca, Sr, Ba, x = 0.1 to 0.5), wherein a fraction of the La in Li6.25Al0.25La3Zr2O12 is substituted with alkaline earth metal elements, in a 100 % O2 atmosphere and allowed the material to cool naturally. The supply of 100 % O2 during natural cooling is particularly important. Li6.25Al0.25La2.8Mg0.3Zr2O12 exhibits a high Li ionic conductivity of 2.7 × 10−4 S·cm−1 at 25 °C. The X-ray diffraction pattern and Li ionic conductivity of the Li6.25Al0.25La2.8Mg0.3Zr2O12 sintered body remains unchanged even after exposure to air for 1 year.

◆Announcement◆

Call for a Guest Editor for the Feature

https://doi.org/10.2109/jcersj2.134.A1-1

https://doi.org/10.2109/jcersj2.134.A1-1A1-1

© Copyright by The Ceramic Society of Japan